Customer Overview

A global third-party logistics company found IPG through a web search and inquired about using a water-activated tape (WAT) case sealer to help automate their packaging process and alleviate staffing issues from manually packaging and taping products.

The Challenge

The company was manually packing and sealing boxes at several stations located throughout the plant. Paying more than 50 employees overtime resulted in significant packaging costs, which drove them to look for a way to reduce labor and improve efficiencies.

Results/Benefits

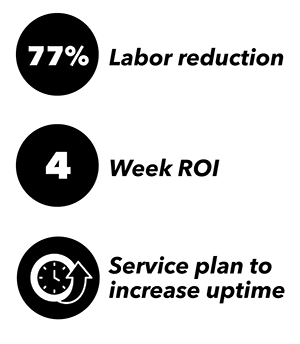

Once the third-party logistics company

reviewed the videos of the RSA 3023-WAT case sealer sealing their boxes, they were sold! They were pleased with the output and they have always been impressed with the security the water activated tape provided to their customers’ packages. The supply

agreement and cost savings allowed them to recover the investment of machine in just four short weeks. They selected a service plan with preventative maintenance to keep their machining running in pristine condition.

Proposed Solutions

They expressed a strong interest in our top-of-the-line, high speed, water-activated case sealer designed to streamline the taping of boxes of all sizes. To provide the most effective solution, we invited the customer to send a sample of their cases to our Machinery Center of Excellence in Ansonia, CT, for a comprehensive trial of carton closure solutions, which was recorded for their review. IPG recommended the Better Packages Random Semi-Automatic RSA 3023-WAT water-activated tape case sealer after the trial. This machine boasts the fastest speeds on the market, capable of sealing up to 18 cases per minute of various sizes. Moreover, IPG also proposed a 2-year supply agreement for the water-activated tape to offset the machine’s cost as well as a bimonthly preventative maintenance program to ensure the machine’s continued peak performance.

Conclusion

In conclusion purchasing the RSA 3023-WAT machine, reduced labor from 30 employees down to 7 people and they were able to reallocate resources within the facility to save time and money in all areas of their supply chain.