Customer Situation

A major industry-leading national e-commerce retailer faced significant challenges in achieving consistent quality when sealing cartons of varying sizes and weights. The customer, along with the IPG corporate account manager, identified this as a potential area for improvement in their shipping process.

Proposed Solutions

- Perform a proprietary adhesion force to kraft test at each location to measure the force needed to break the bond between tape and corrugate.

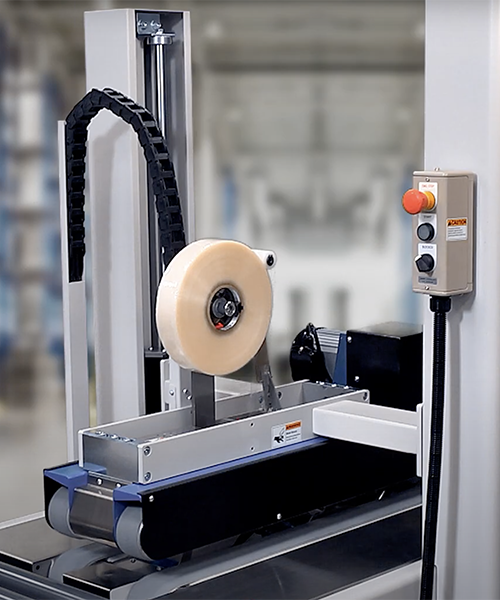

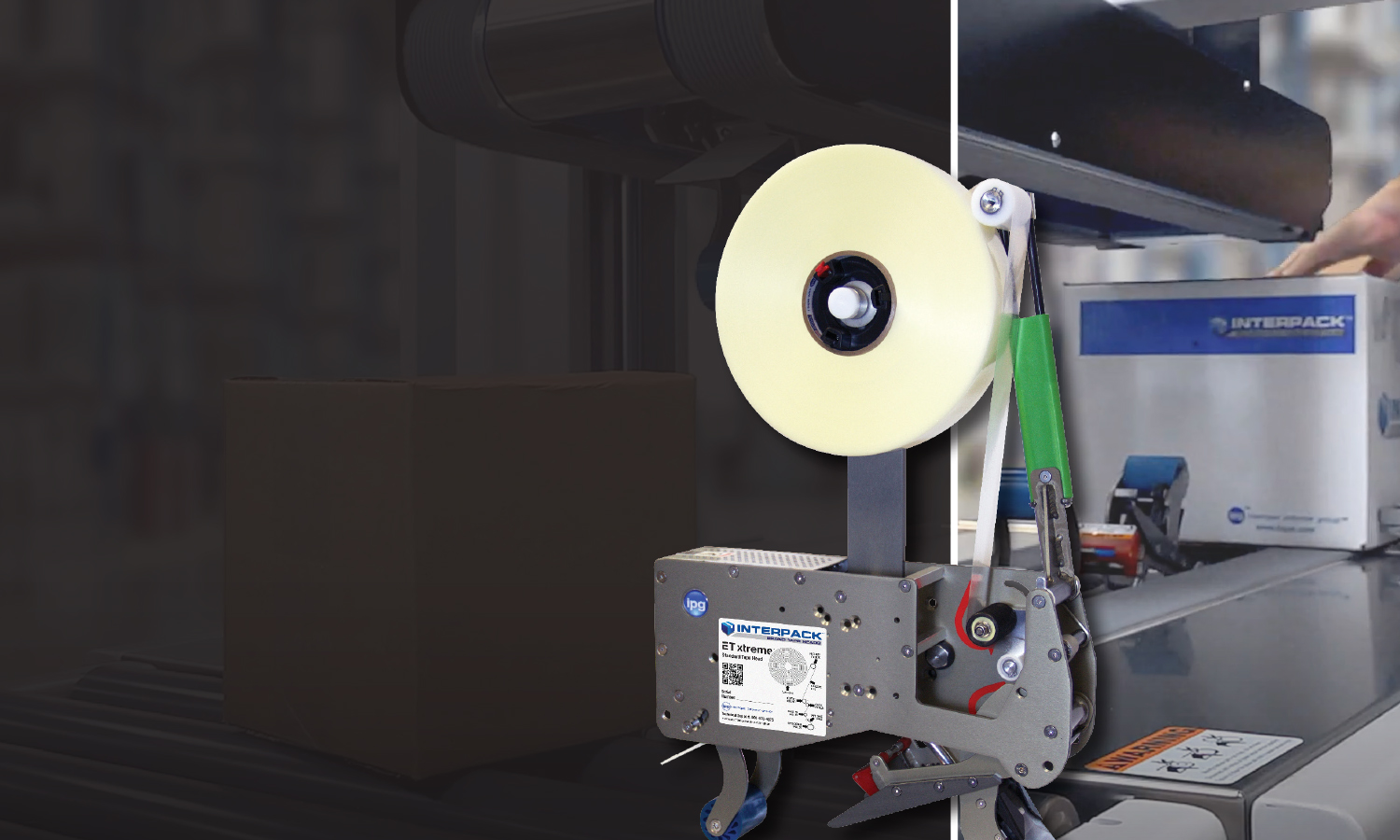

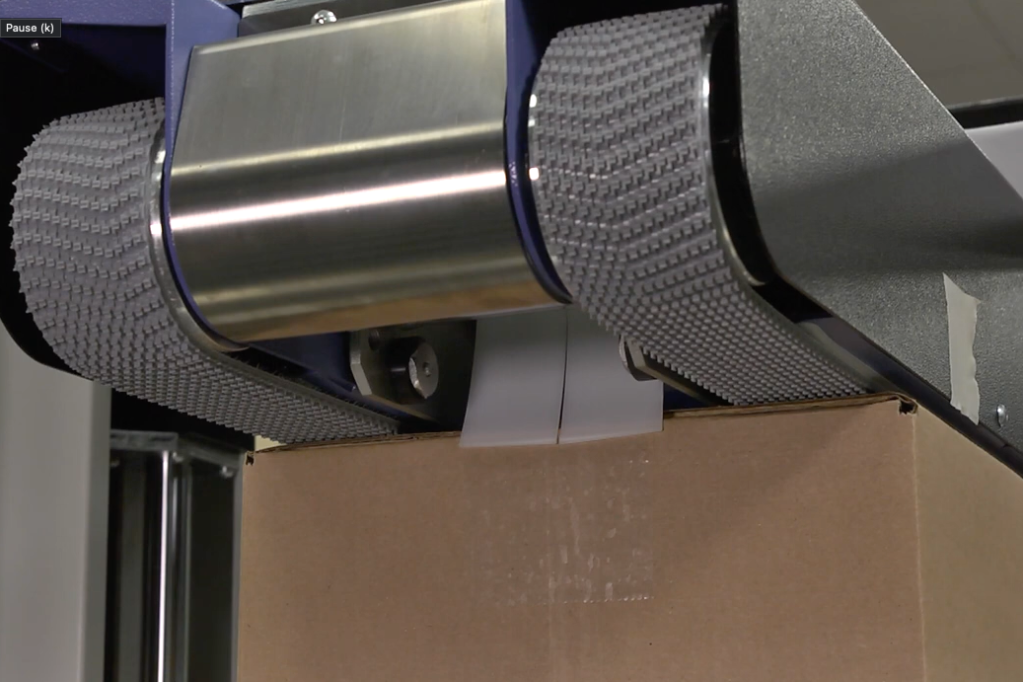

- Install IPG’s ET Xtreme® (ETX) tape head for superior wipe-down force, lighter

weight, and increased speed. - Test lighter tape, as ETX’s wipe-down

ability and IPG’s Corru-grip® adhesive

allow it to seal as effectively as heavier

tape. - Install IPG’s iTrack™ low tape/no tape

sensors to capture critical performance

data. Establish a service program for

IPG technical staff to conduct regular

maintenance on equipment and tape

performance.

Results

- Adhesion force to kraft showed 132% more force needed to break the seal with IPG tape than the competitor’s.

- Replaced all competitor tape heads with IPG’s ETX head.

- The ETX tape head enabled customer to move to a lighter tape which provided a 17% material savings.

- IPG installed iTrack™ low tape/no tape sensors allowing the customer to access data to increase efficiencies on each production line.

- IPG’s Cradle to Cradle® Bronze carton sealing tapes allowed the customer to use the tape change to meet their sustainability goals.

- The customer agreed to a service contract for IPG’s technical team to visit locations on a regular basis, ensuring efficient operation of equipment and allowing the customer’s internal maintenance staff to focus on other areas.

- IPG helped the customer achieve minority spend goals by purchasing from a minority owned vendor.